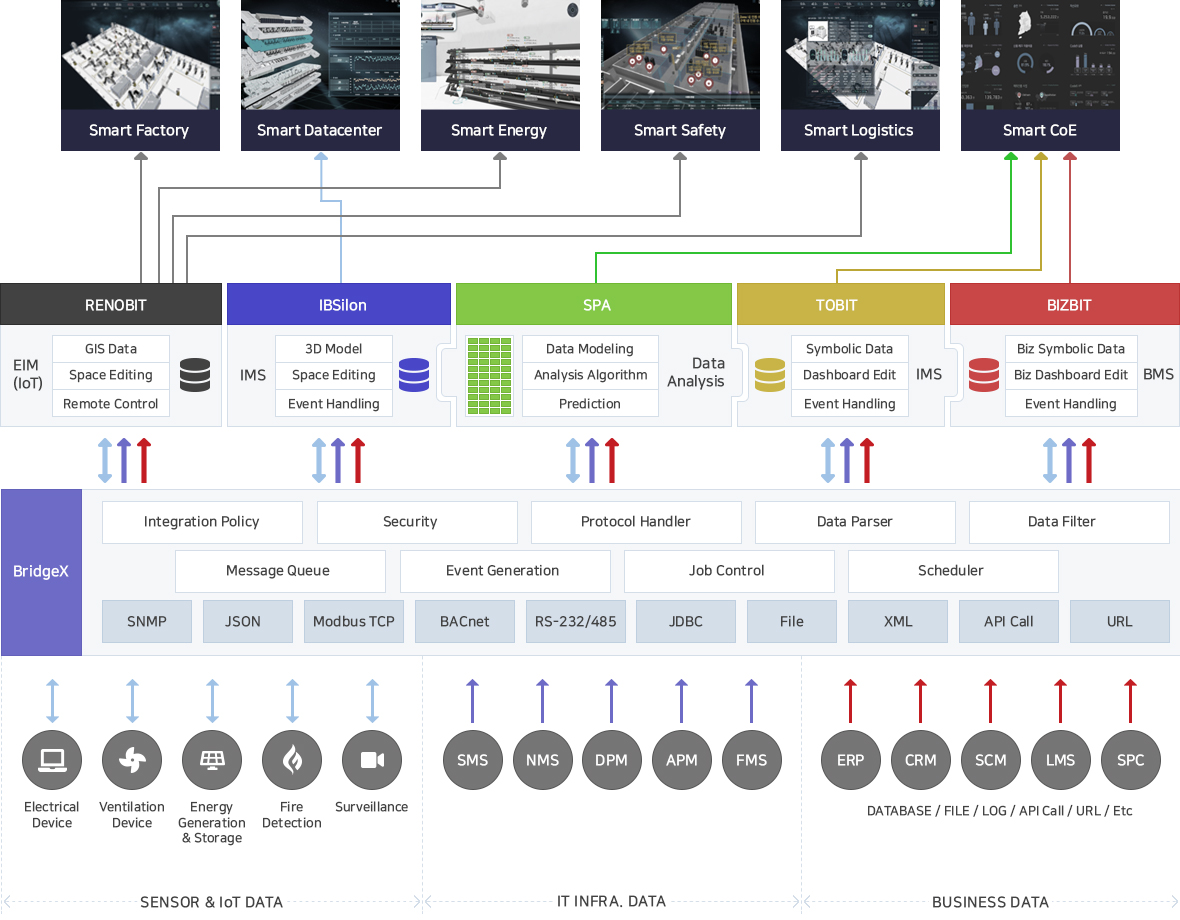

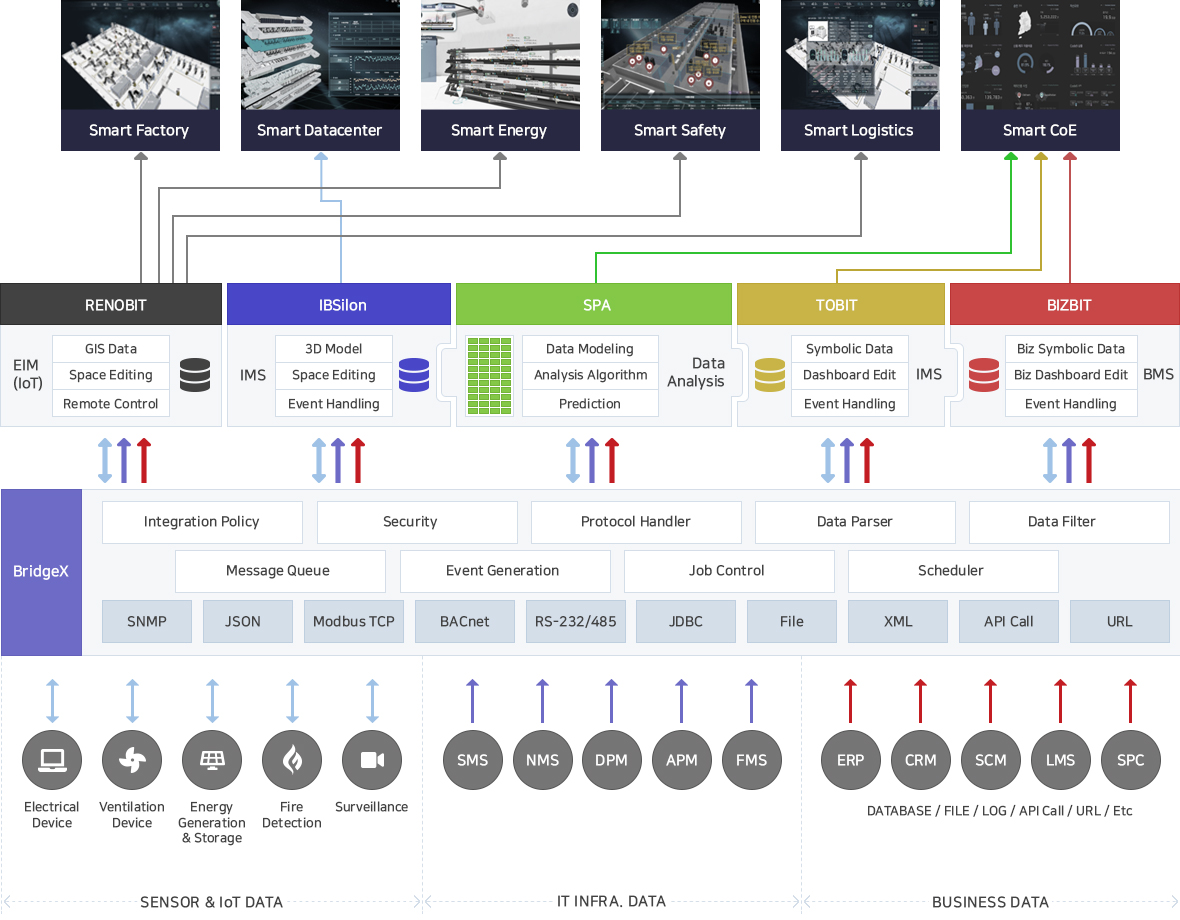

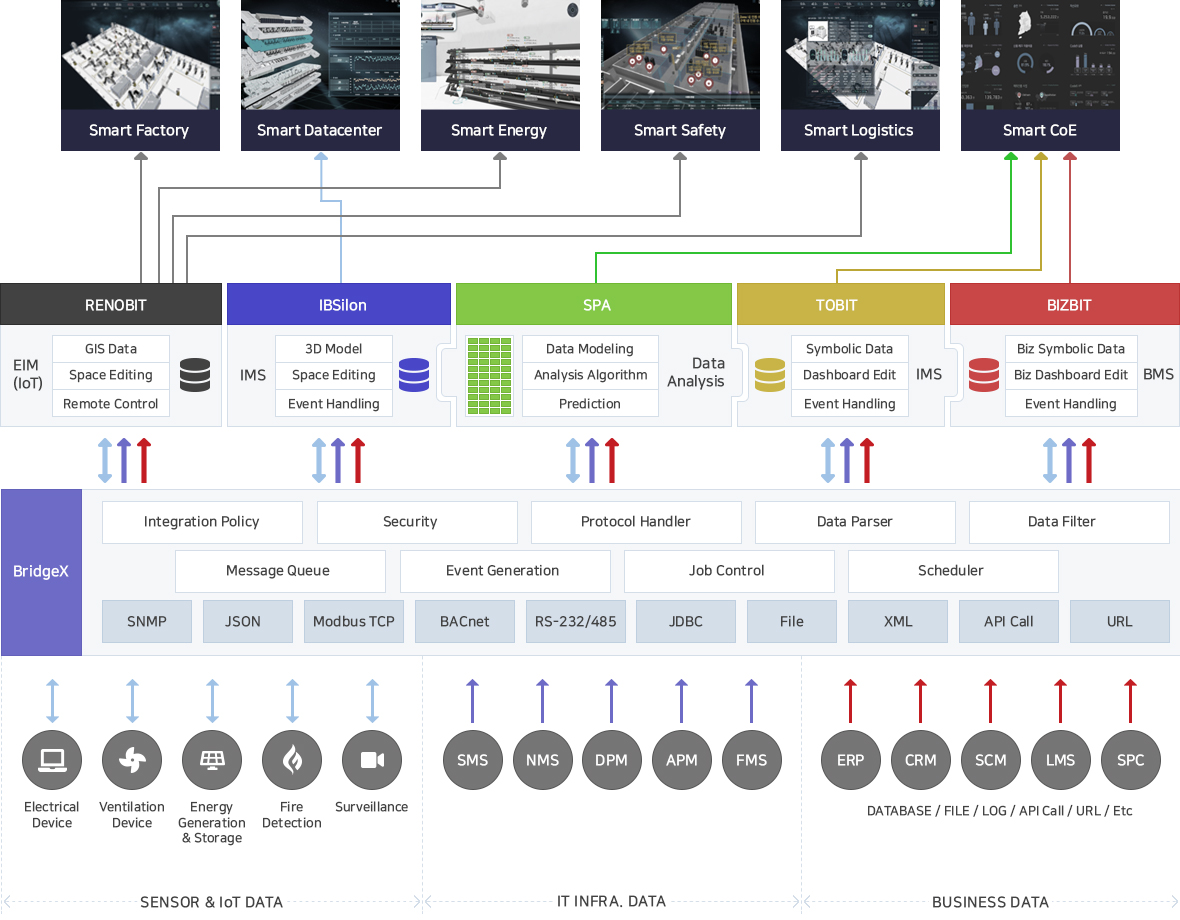

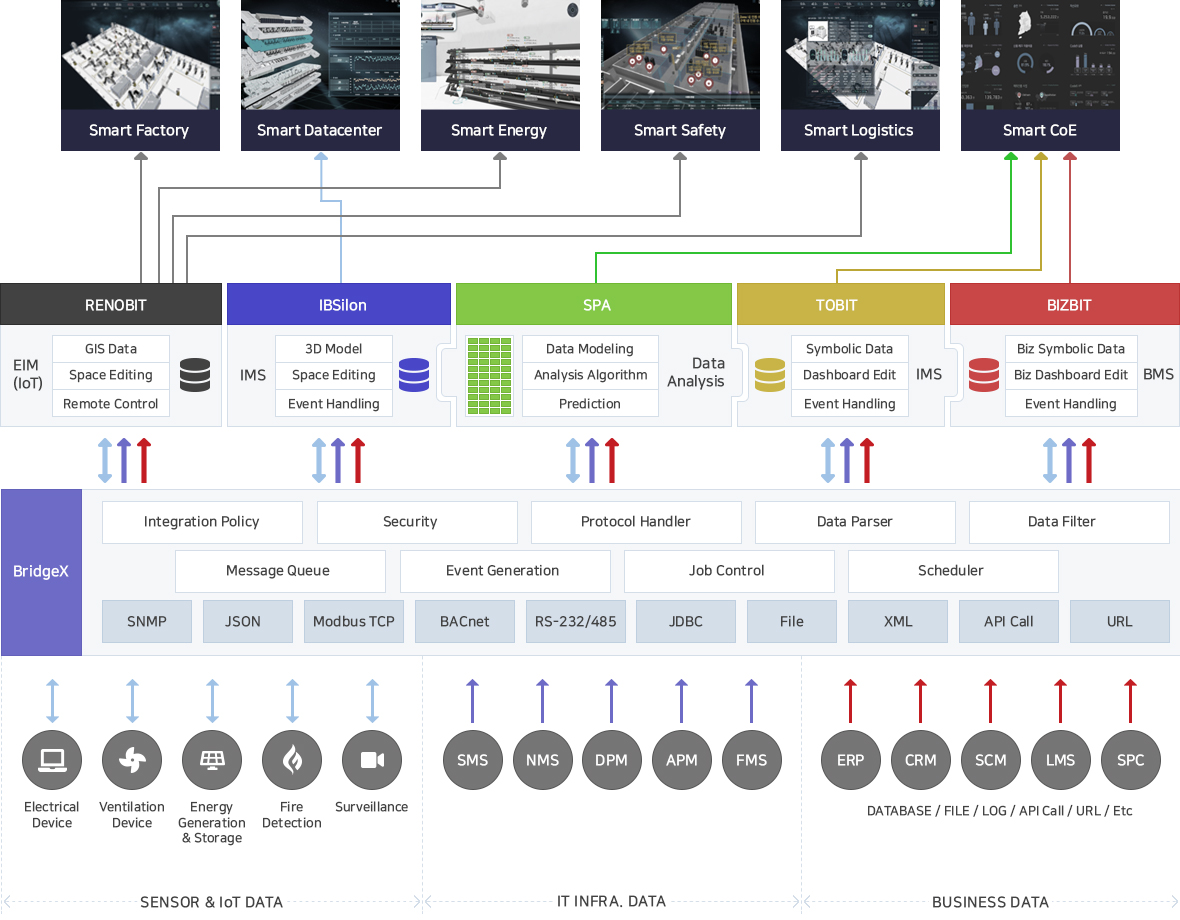

It provides big-data-analysis-based business monitoring services like energy, manufacturing sector, and production management by expanding the scope of the existing system beyond the existing IT infrastructure and facilities management.

The optimal system applied with real-time data processing and the IoT technology provides a real-time failure and demand prediction function based on process-specific status monitoring and indicator data analysis.

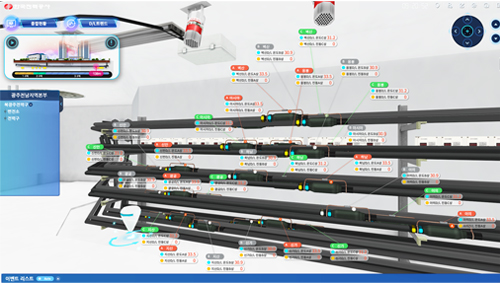

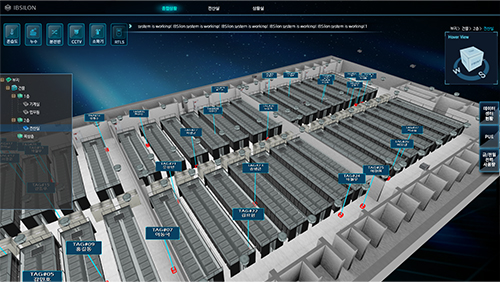

Monitoring and controlling remotely by linking the sensor data in real time

Reflecting colors to the node icons according to the status

Indicating failure to the sensor data when events occur

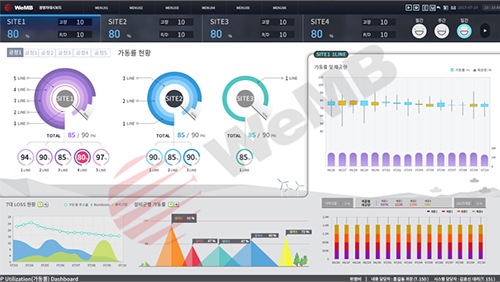

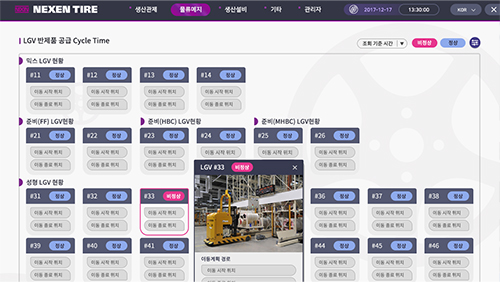

Performance trend by the operating goal per major line

Comparative analysis of the cause of the decline in the operating rate and the status of the major facilities group

Performance status and comparison trend by the entire production goal

Cross-comparison of the sub-indicators, including the work-in-progress status, operating rate, and achievement estimation of each line

Monitoring the status of whole facilities, total output, and staff within the production process

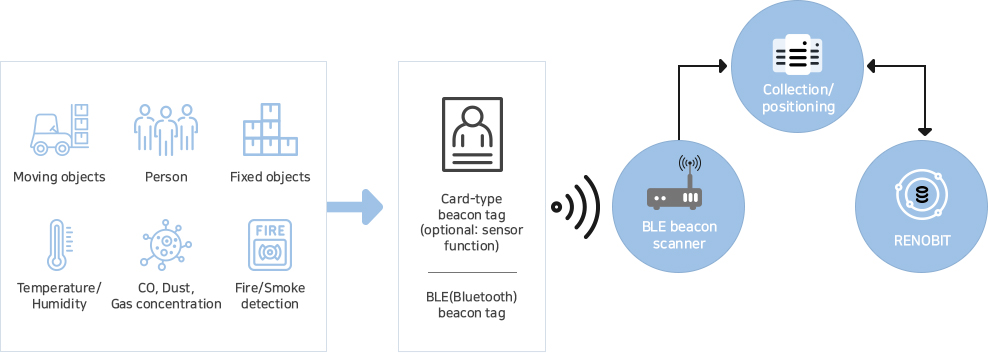

Monitoring the abnormal situations through fire detection, CCTV, location tracking, and remote control

Monitors various objects in factories and industrial sites by locating and tracking the moving route through object scanning

Prevents casualties with quick responses, such as access control or emergency guidance in case of danger